Leading Specialists at Hot Glass Forming and Ware Handling for Automatic Production Lines

D A Oldfield Ltd. are known worldwide for their technical excellence in providing individual solutions to customer’s problems of delivering hot glass containers from the feeder and forming machine to the ware handling and Lehr without, loss or contact damage. This involves the supply of our designs from the feeder to the ware handling machinery and more recently stainless steel felt insulation materials and parts to eliminate contact faults, from pushers, transfer fingers, stacker push bars and neck guides.

Our customers benefit from having personal contact with our management, which often builds long lasting partnerships and a trust that their needs are being taken care of efficiently.

Quality driven innovation and the application of new materials and technology keep us ahead of the competition. Our history of working

within glass plants since 1956 and having membership of the society of glass technology for over 30 years bears testament to our commitment to producing glass more efficiently.

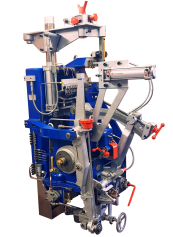

Introducing D A Oldfield's Advanced Loading Systems (ALS)

The DAO Advanced Loading System has been designed and built to improve gob loading, aiding your production. With over 150 Advanced Loading Systems sold over the world on all sizes of new and used IS machines, can you afford not to do the same?

Loading problems the ALS helps to correct:

☼ Gob drift - gobs are thrown off centre by shearing. This results in loading marks and slower movement through the troughs and deflectors

☼ Gob rotation - gobs start to rotate due to shearing or long gob shape. This results in loading marks and slower movement through the troughs and deflectors

☼ Conventional shear sprays apply lubricant to only one side of the gob distributor funnels. This results in dragging on one side of the scoop and reduces gob speed.

☼ Sectional differences - larger machines suffer from different loading times between the inner and outer sections. This limits the machine speed and gives inconsistencies across the sections

☼ Gob interaction - multi-gob delivery results in drift created by the Bernoulli effect due to the distance between the shear point and gob distributor. This results in loading marks and slower delivery.

Click through to find out more, or get in touch today on either

+44 (0)1904 607086 or sales@daoldfield.co.uk